Flexcrevator: An Innovative and Novel Pit Latrine Emptying Device

2017 - 2019 • North Carolina State University (NCSU, NC State)

Purpose

Meeting the need of billions: an efficient and hygienic pit emptying device.

Activities

NC State partnered with Tri-EHI and Catapult Design to field test, perfect, and assess the market for the Flexcrevator. We field tested the device in Lusaka, Zambia in fall of 2017. We will perform another round of testing this summer (2018) in Kenya. The team will execute final testing with engineering validation units in Malawi, South Africa, Rwanda, Zambia and Kenya later in the year.

We are currently recruiting commercial partners interested in the manufacture, distribution and sale of the device.

Images

Countries of activity

Location of main activity

Objectives

Every day, pit latrines receive an estimated 0.6 billion kg of feces and 2.1 billion kg of urine from 1.77 billion people around the world. Once pits are full, fecal sludge has to be removed, before being transported and treated/reused. It is unbelievable that manual emptying of pit latrines using buckets and shovels still exist today - a high-risk, unsanitary, and undignified job. While mechanized ways to remove fecal sludge from latrines exist, these devices are often inefficient, too bulky, or too expensive for the average pit emptier to own. They also clog frequently from high volumes of garbage in the form of rags, plastic bags, bottles, and hair. Vacuum truck operators or other smaller vacuum-based systems choose not to empty pit latrines on account of high trash concentrations.

One of the biggest challenges in this field is developing a single pit emptying technology that can empty trash-filled pits at a competitive cost. This project is an extension and broadening of a program originally started with funding from the Bill and Melinda Gates Foundation (BMGF). NC State received funding from the foundation to develop, test, and optimize the our innovative pit emptying device beginning in 2011. Our device removes fecal sludge even in the presence of trash in pits, making emptying faster and more hygienic than manual methods. The aim of the project is to redesign the prototype machine so that it is widely adopted by pit emptying service providers and entrepreneurs, and also ensure that the enhanced Flexcrevator can be economically manufactured.

Further information

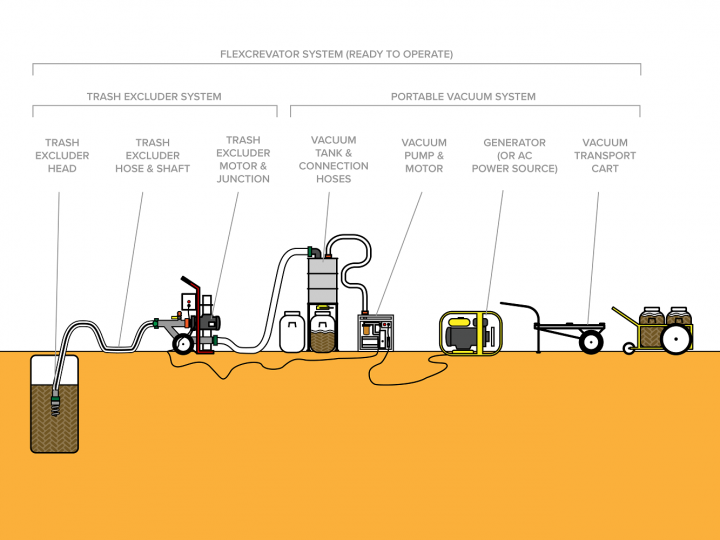

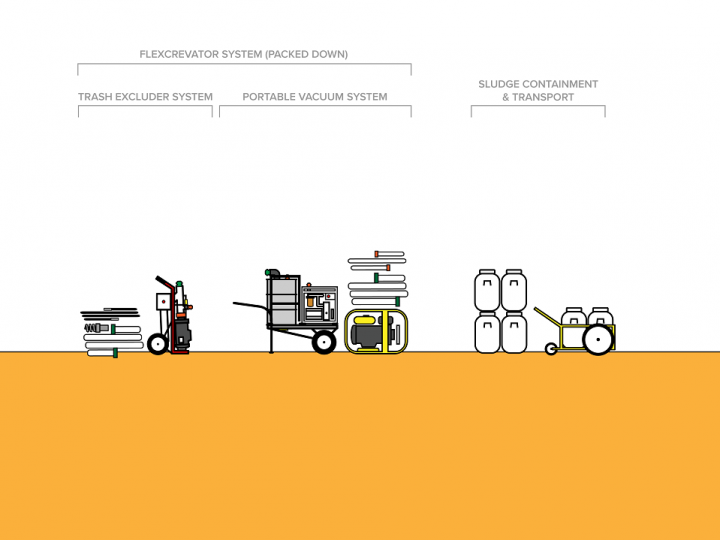

This machine has two main components – a vacuum cube and an external trash excluder. The parts work together to simultaneously exclude trash while quickly extracting fecal sludge. The trash excluder in its current version is a rotating auger that pushes trash away during fecal sludge pumping. The operator empties fecal sludge from the vacuum tank and into sealed plastic barrels for safe storage and processing off site. Each component can be easily lifted for transport and storage. If a pit emptier already has access to a vacuum truck and pit access is not an issue, the user also has the option of connecting the trash excluder directly to a vacuum truck to help empty pit latrines with very high trash concentrations.

The Flexcrevator surpasses manual emptying by providing a safe, hygienic process for workers. When using the Flexcrevator, pit latrine emptiers have less opportunities for direct contact with raw fecal sludge. Our unit has competitive advantages over vacuum trucks as its small, modular, footprint allows workers access to pit latrines in narrow alleyways that usually restrict vacuum truck access. In terms of price point, the overall device is 10-20x cheaper than a vacuum truck. Unit's cost is nearly 50x cheaper than the standard vacuum truck under commercial production levels. While vacuum trucks are typically imported into developing regions, we designed the Flexcrevator with local manufacturing and sourcing in mind, allowing for lower maintenance costs. Finally, if a vacuum truck operator uses a trash excluder on an existing truck, the operator gets a competitive advantage over other truck operators as our excluder opens new business opportunities to empty trash filled pit latrines.

Contact information

Francis de los Reyes III

Login to see the e-mail-adress of the contact person.

Jocelyn Tsai

Login to see the e-mail-adress of the contact person.

Filter tags

Bill & Melinda Gates Foundation Emptying and transport (non sewered) Global Peri-urban Practitioners Product design and engineering Sub-Saharan Africa University, education or research institution Urban informal settlements (slums)

Links

North Carolina State University

Raleigh

United States

Uploaded by:

Jocelyn Tsai (jocetsai)